INTERTEK ADDS WHOLE-SHOE COMFORT TESTING SERVICE

To meet the comfort and health characteristics of footwear desired by consumers and enterprises, Intertek has introduced the Endofoot (for advanced moisture management testing - AMMT) tester and added the whole- shoe comfort testing service.

This service includes both moisture vapour permeability and thermal insulation testing to help manufacturers seize the immediate market opportunities as well as meet consumers’ demand.

OUR STRENGTHS

Whole-shoe comfort testing service, with human-inspired testing process and multiple reference test results:

- The test sample is the complete footwear so as to avoid the potential issue of materials being breathable but not the complete footwear.

- Uses sweating environment at 38°C in accordance with a real shoe being worn.

- This tester replicates distributed ‘sweat’ dissipation in the form of vapour which simulates what happens with a real shoe being worn.

-

It is considered the only test process for complete footwear to quantify heat management characteristics, with test results that are accurate and useful.

MOISTURE VAPOUR PERMEABILITY

If sweat cannot be absorbed by the shoes or dissipate outside quickly enough, it could create a humid environment which reduces the comfort of the shoes and make them unwearable. It also encourages fungus growth. It is important to have a pair of shoes that breathes as they keep your feet dry reduce the risk of "athlete’s foot"!

THERMAL PROTECTION

The warmth of shoes is very important for people with special requirements or who are in a specialised environment, such as climbers and those who engage in outdoor activities during winter, and especially the elderly and children. Not only does hypothermia affect comfort, it also causes physical injury and even endangers life.

TESTING PRINCIPLE

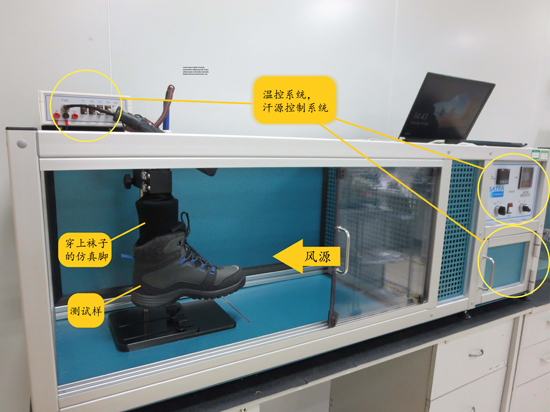

This machine has been developed to assess the thermal and sweat management performance of complete footwear by measuring thermal insulation, moisture absorption and breathability properties.

The foot of the shoe, which incorporates electrical heating elements and water supply pipes that distribute ‘sweat’ (water) to the surface, is first fitted with a standard reference sock. After a period of warming up to reach equilibrium, a realistic warm and humid environment is created to replicate that which is found inside a real shoe being worn. The dressed foot is then subjected to a calibrated flow of air over its surface to replicate movement through the air when walking, (which helps to dissipate any moisture transmitted to the surface of the shoe). The amount of sweat absorption of shoes can thus be calculated by weighing the shoes, and the amount of sweat dissipated is the amount of moisture lost.

In operation the test for thermal properties uses a moulded foot form to conduct a cold rating to determine the thermal properties (insulation) of footwear. Footwear comfort can then be assessed against guidelines for a certain external temperature and activities level.

Intertek is a leading total quality assurance provider to industries worldwide. It has a history of more than 130 years, and companies around the world have depended on Intertek to help ensure the quality and safety of their products, processes and systems.

Intertek Softlines footwear laboratory has a strong technical team committed to the research of the function, safety and comfort of footwear. It makes use of professional testing technology and has accumulated vast experience in testing to provide you with professional service and pinpoint requirements for your products.

For more information ,Pls contact :

Mrs. Ella Wan

Tel: 020-2820 9361

Email:ella.wan@intertek.com